matthew luongo

Mechanical Engineer

Welcome to my interactive resume and portfolio.

Bio

I'm a born engineer with a penchant for creative problem solving. I'm always seeking out new challenges, and I strive to pick up skills wherever and whenever I can. Apart from my technical skills, I'm easy to get along with. I can mesh well with any team. Outside of work, you can usually find me cooking, baking, or relaxing with my cats. I also enjoy video gaming, collecting music, gardening, and birdwatching.

Experience

I have two and a half years of professional experience across full-time non-internship roles. In my current role at Hamilton, I create electromechanical and sheet metal assemblies for life sciences products. I've also had plenty of opportunities to pick up new skills. Check out more details of my experiences with the buttons below.

Educaton and School Projects

While obtaining my BSME and MSME at Northeastern, I met countless wonderful people and gained a wealth of knowledge in technical subjects. Click here for a list of interesting, challenging, and rewarding school projects I had the opportunity to complete.

Hamilton Storage

My tenure at Hamilton Storage has been filled with new learnings and experiences. I worked on the BiOS automated sample storage system and the LabElite line of robotic laboratory products. Read about my projects here.

Hamilton Storage

Mechanical Engineer II

April 2024 – Present

Franklin, MA

I love when my work has an impact. At Hamilton Storage, I'm fueling biotech, sample storage, and clinical diagnostics with industry-leading automation.

| Product Types | Automated sample storage systems Robotic laboratory devices Large machinery |

| Big Projects | Lid lifter redesign and industrial design overhaul for Hamilton BiOS Camera array design for LabElite product line |

| Skills | 3D modeling, GD&T, DFX, mechatronics, electro-mechanical assemblies, vision systems, test fixturing, breadboarding, sensor selection, 3D printing, microcontrollers programming, rapid prototyping, basic PCB layout, work procedures, risk analysis, large drawing packages, EU regulations |

| Software | SOLIDWORKS, Excel, Arduino, Python, Jira, D365 |

| Milestones | Experienced my first product design cycle Completed GD&T and product design trainings |

LabElite Camera Array

I designed a camera array for the LabElite line of automated benchtop devices. Many lab devices use mirror-based camera setups to capture barcodes on the bottom of sample tubes. I devised a close-distance camera array with high enough depth-of-field to produce exceptional images. My camera array reduced BOM cost and alignment time while being twice as compact as the previous solution.Before arriving at my solution, I researched experimented with several imaging technologies and a range of hardware. I designed test fixtures to mount cameras, lights, and optical diffusers, and wrote scripts for basic image stitching and storing.

BiOS Lid Lifter Redesign

I redesigned the lid lifters that keep samples secure in the BiOS. This project had a couple design constraints: it had to be retrofittable, and it had to use a specific linear actuator. I created a simple, reliable assembly with ambidextrous parts that allowed left- and right-handed assemblies to use the exact same BOM. My electro-mechanical lid lifter saved days of install time by replacing an older design.During the ideation process, I experimented with hinge designs before arriving at my simplified final design. I enjoyed learning about kinematic synthesis and linkages during this project.

Kinematic analysis of linkage

My design showed minimal signs of wear after life testing in a -20°C environment. To wrap up the project, I created detailed work instructions and installation documentation and validated the first build with the manufacturing team.

This design effort was paired with several design reviews and a constant stream of information to a cross-functional team, ensuring a smooth transition from the old design to the new one.

Bios Industrial Design Overhaul

In this large-scale endeavor, I overhauled the BiOS industrial design to improve the mounting of refrigeration cover panels. The result was a significant reduction in install time and a much smaller BOM.

My design offered a singular BOM for both left- and right-handed systems, relying instead on configurable parts and clear assembly instructions. The redesigned panels also reduced hours of low-value floor time by shifting assembly to manufacturers, where possible.I also devised a mounting scheme for the TV on the front that used a cool magnetic drill fixture.

Other Projects

Working at Hamilton enabled me to practice a ton of different skills on a variety of projects. It was fun to design a new test fixture to evaluate a specific sensor. I also took every opportunity to develop my programming skills. I even created a simple PCB that halved the cost of a sensor solution.

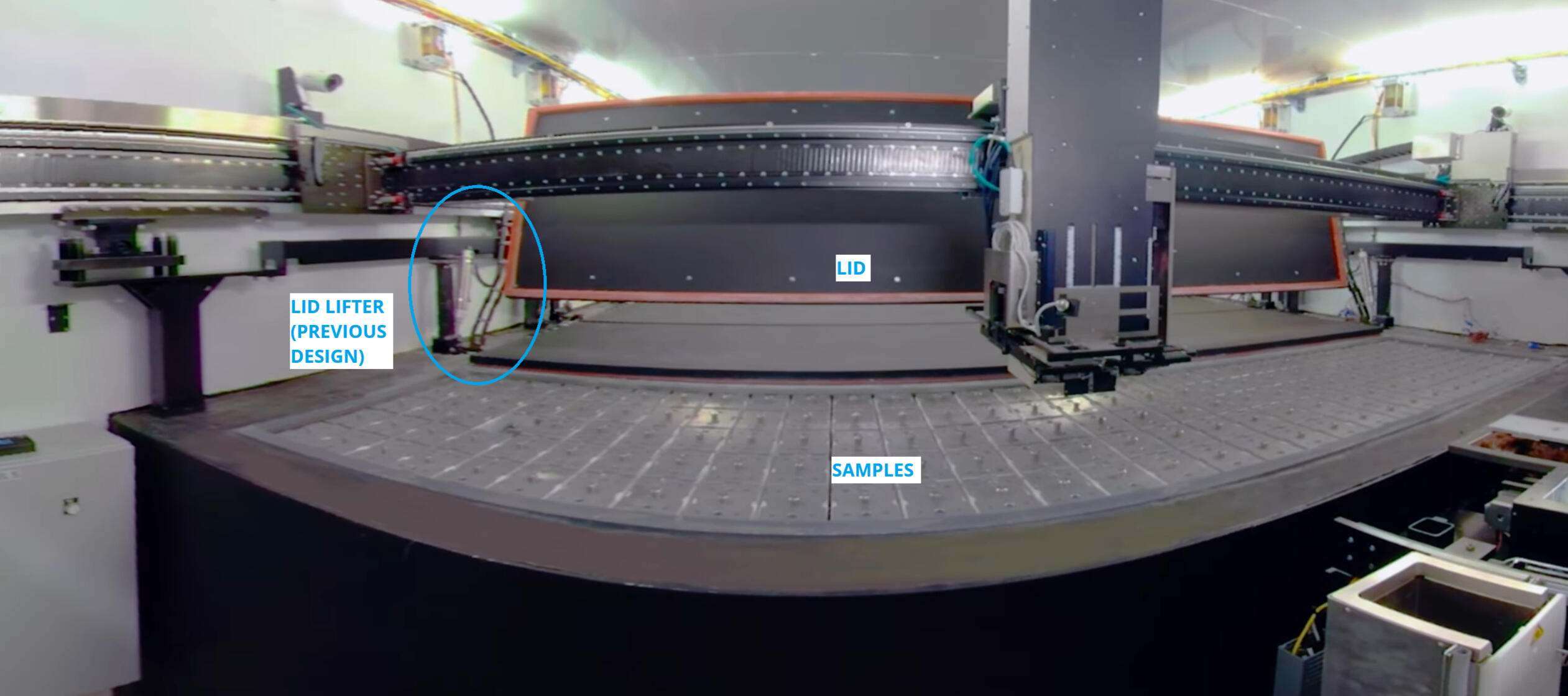

About the BiOS

BiOS is a large, complex -80°C storage system with a high sample density. BiOS installations are bespoke construction projects, and installation time tends to be a large portion of the cost. Shortening install time through design improvements saves thousands of dollars and quite a few headaches.

In the video above, you can see the pneumatic lifter design starting around 0:18. These older lifters needed tubing routed throughout the system. They also required cavities underneath, which necessitated complex assembly and disassembly steps during the foaming process.

You can see the previous lid lifter design here

BiOS systems come in 'left-hand' and 'right-hand' variants. These terms refer to which side of the system holds the refrigeration modules. There are advantages to designs that offer flexibility between several configurations without needing a separate BOM.

Desktop Metal

Desktop Metal afforded me the opportunity to work with many brilliant engineers. I supported large 3D printers intended for production quantities of metal parts and sand molds. Read about some of my projects below.

Desktop Metal

Mechanical Engineer

July 2023 – January 2024

Burlington, MA

In my first full-time role, I supported engineering efforts for production-level 3D printers at Desktop Metal.

| Product Types | Metal and sand 3D printers Large Machinery |

| Big Projects | Flex Coupling Project |

| Skills | Sheet metal, pneumatics, P&IDs, test fixturing, 3D printing, machining, rapid prototyping |

| Software | SOLIDWORKS, Jira, Arduino, Propel, Vizio |

| Milestones | Presented my first design review (flex coupling project) |

Projects

Flex Coupling Replacement

I sourced replacement flexible couplings on a small-factory-sized printer. Existing PU couplings had low pressure ratings. When the system was purged, those couplings ballooned to disturbing sizes. My task was to find flexible couplings that could withstand 7+ gpsi while being compliant enough to manipulate by hand for frequent disconnects and reconnects.

Ballooned coupling compared to unstressed coupling

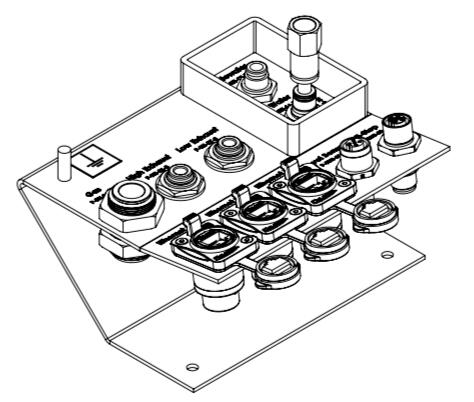

Facilities Plate Redesign

I redesigned the facilities plate for a large 3D printer.

Redesigned facilities plate

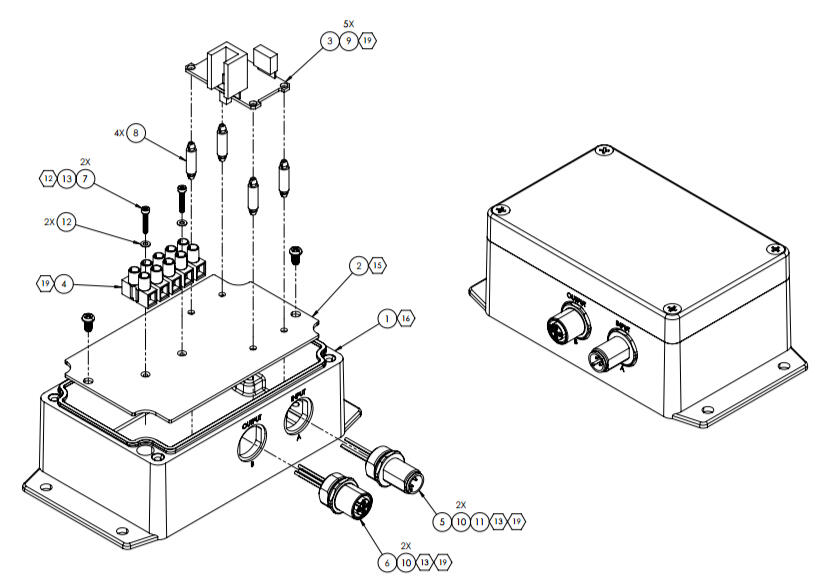

Proportional Valve Upgrade

I upgraded a large 3D printer with a new proportional valve.

Proportional valve enclosure assembly drawing

Co-op Experiences

My two co-ops served as an excellent starting point for my professional career. Read more about my co-op experiences here.

Co-op Experiences

At Northeastern, I completed co-ops at Covaris and Amphenol Alden. This valuable experience was a kickstart for my professional career.

| Product Types | Benchtop lab products Connectors and cables for medical devices |

| Big Projects | Alignment tools Blowoff Fixture Custom overmolded enclosure |

| Skills | 3D modelling, manufacturing tools, work procedures, clean rooms, change orders, engineering documentation |

Covaris

Manufacturing Engineering Co-op

July 2021 – February 2022

Woburn, MA

At Covaris, I supported the manufacturing engineering team as well as the manufacturing floor. Aside from building and calibrating their machines, Covaris also manufactures various types of consumables. As one project, I created alignment tools for a robotic RNA shearing instrument. For another project, I redesigned, assembled, and installed a blowout fixture into a cleanroom.

Amphenol Alden

Design Engineering Co-op

January 2020 – June 2020

Brockton, MA

During my first co-op experience, I supported the design engineering team with design updates, creation of documentation, and work on custom projects. I learned about injection molding and cable design between drawing changes, test activities, and change orders.

School Projects

At Northeastern, I took a number of interesting and enriching courses. School projects allowed me to learn new skills and explore a variety of subjects.

Education

BSME, MSME from Northeastern

September 2018 – May 2023

Boston, MA

I received my bachelor's and master's degrees from Northeastern University, attending from 2018 to 2023.

| GPA: | 3.54 - Undergraduate 3.83 - Graduate |

| Courses | Mechatronics, Robot Sensing and Navigation, Robot Kinematics and Control, Finite Element Method, MEMS |

| Software | SOLIDWORKS, MATLAB, Simulink, Ansys Workbench, APDL, C++ |

Annealing Attachment for 3D Printer

Capstone Project

My capstone team designed an attachment for a 3D printer that enabled targeted, in-situ annealing on semi-crystalline polymer parts.

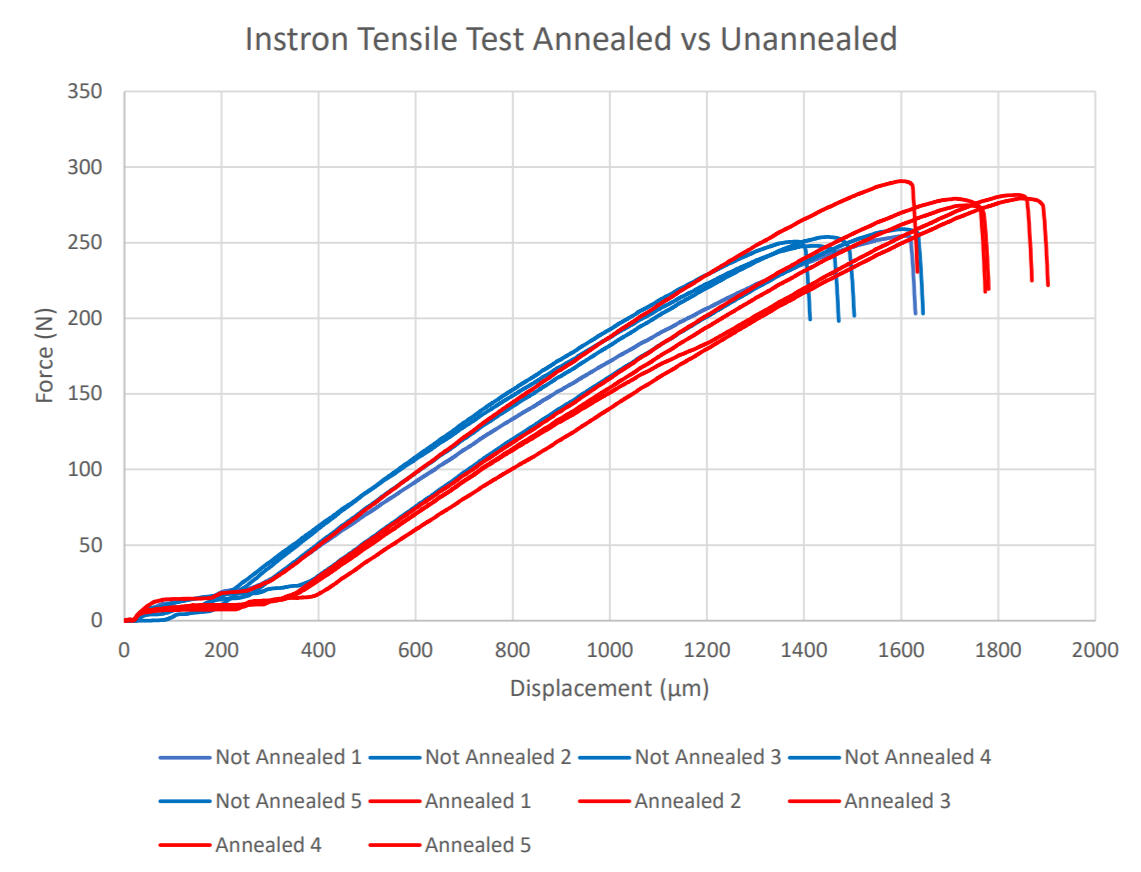

My contributions included control code and enclosure design. Overall, our project was moderately successful. We showed a 12% increase in ultimate tensile strength on test speciments after targeted annealing on a planned failure point.

Tensile data of annealed and unannealed test specimens

GPS and IMU Sensor Fusion

Robot Sensing and Naviation

I wrote drivers for a GPS puck and an IMU in Python. I implemented these drivers in real-time using ROS and collected data while driving around the streets of Boston. During this project I calibrated magnetometer data, estimated position with forward integration, and tested a complementary filter.

Simple Manipulator Simulation

Robot Kinematics and Control

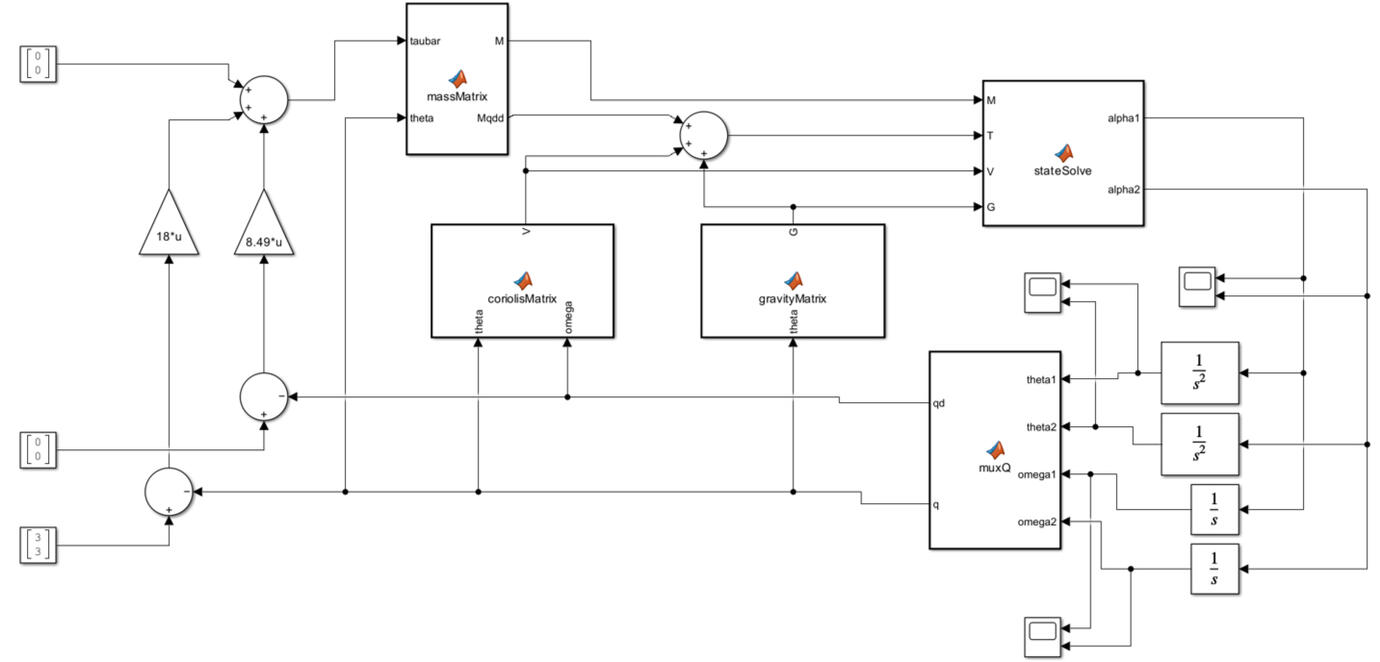

I created a simulator for a two-link manipulator in Simulink.

Manipulator simulation in Simulink

Position and Speed Control of a DC Motor

Mechatronics

I created a control loop in Simulink and implemented it on a real DC motor using an Arduino and breadboarded circuitry. I also compared my custom controller to a simulated model in Simscape.

Metamaterial Analysis in APDL

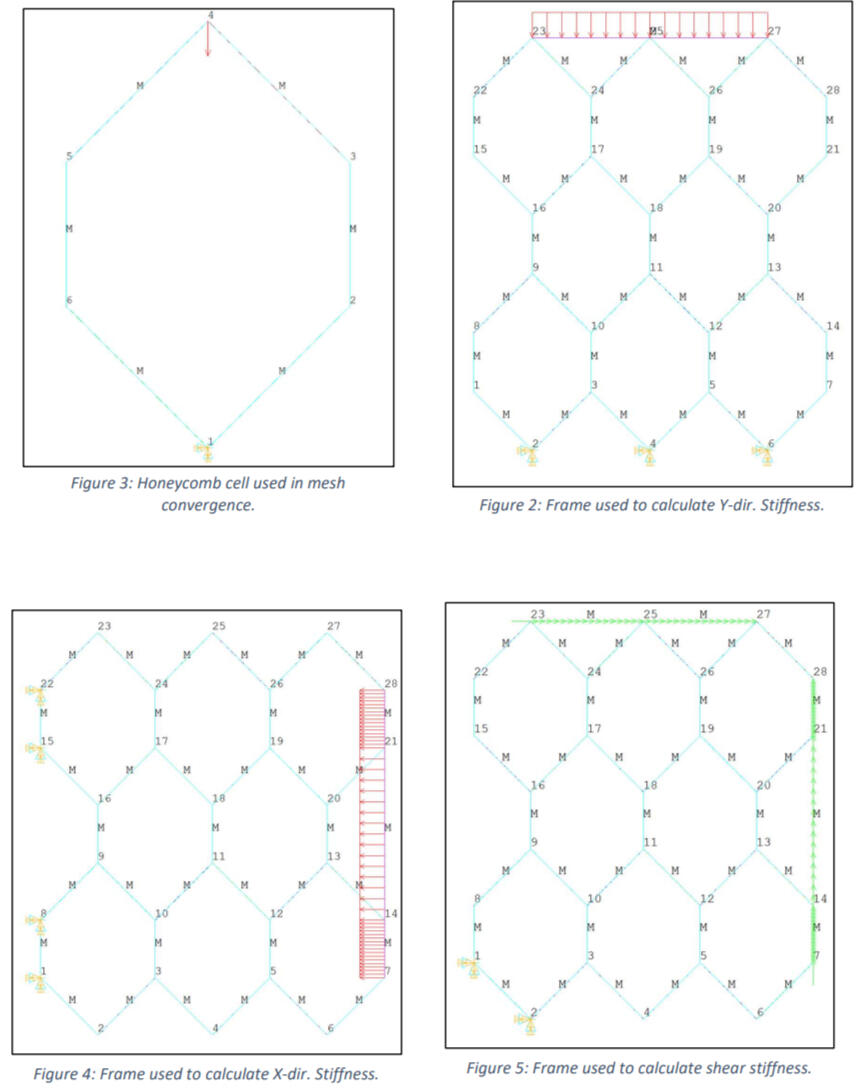

Finite Element Method

I analyzed a honeycomblike frame in APDL to study the properties of an anisotropic metamaterial.

Frames and boundary conditions in APDL

Bonus Project — Swerve Module

High School Robotics

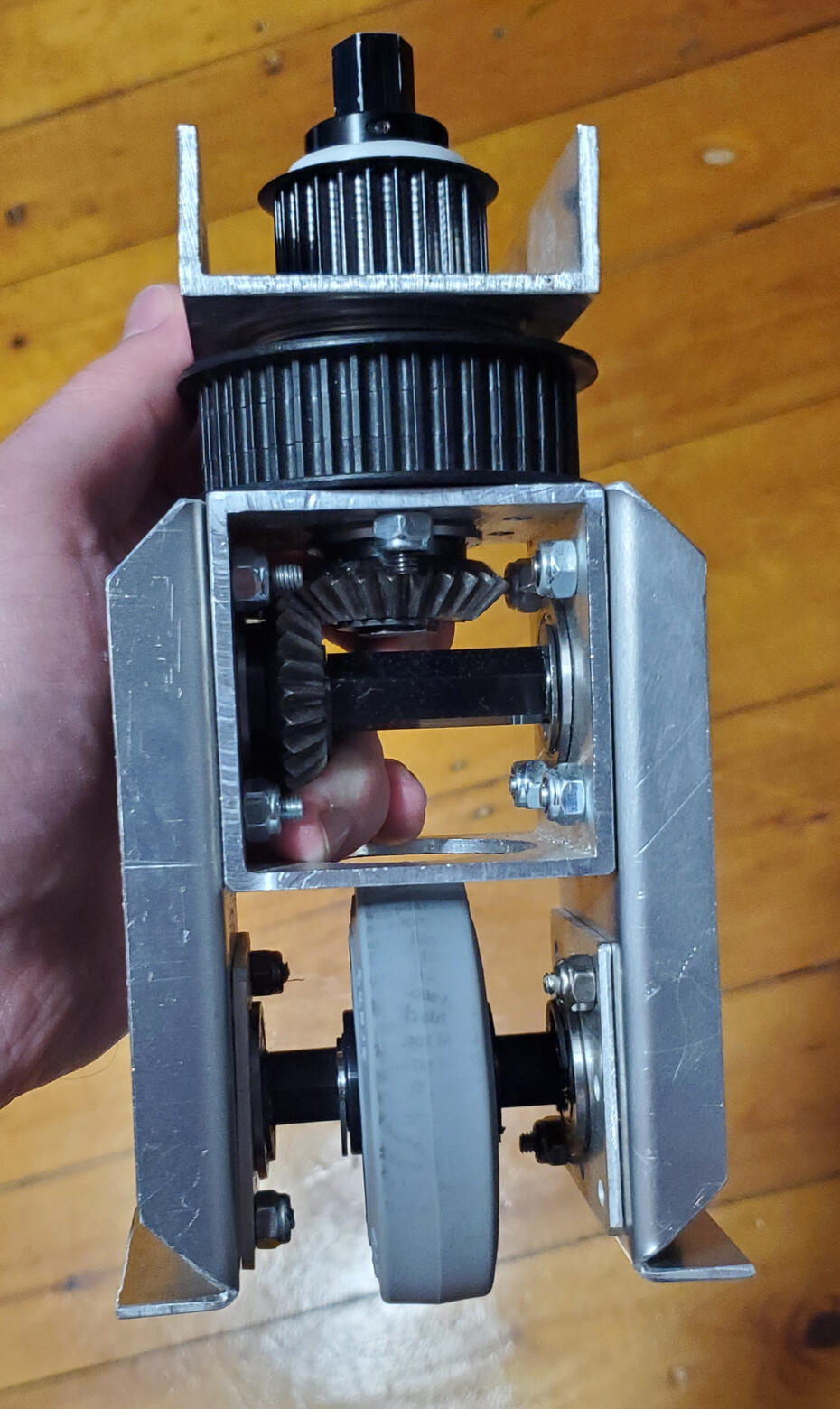

In high school, I designed and assembled this swerve module, which I'm still proud of. All custom parts were fabricated by me.

Custom swerve module, which features a coaxial driveshaft and alignment pulley

PDF embed plugin was developed by Jason Leow.

Not working? Click the document icon on the home page for a Google Drive link.